Beissbarth MB Q.Lign Wheel Alignment

Call us now on 01823 328530 for more details

Manufacturer Approved Zero-space Wheel Alignment

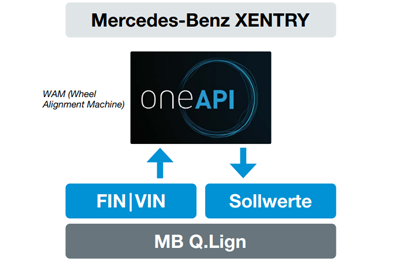

The MB Q.Lign is a Mercedes-Benz approved wheel alignment system that modernizes the alignment process by moving beyond the traditional trolley setup. It eliminates the need for a PC-trolley and physical printer, as image processing is handled directly inside the sensor head and reports are generated as PDF files available on the network. This system is wireless, battery-powered (offering >19 hours of runtime), and designed for operational flexibility, allowing technicians to make adjustments standing up tall in any lift position using intuitive software and easy guidance through MB test procedures.

A core feature of the Q.Lign is its connectivity and automated vehicle selection: technicians simply scan the vehicle identification number (VIN) using a tablet to automatically start an online query, providing immediate, 24/7 access to the latest OEM vehicle specifications directly from Mercedes-Benz, which eliminates manual selection and minimizes errors. Furthermore, the system integrates seamlessly into workshop networks, allowing direct access to all measurements, facilitating direct PDF downloads for sharing, and enabling technicians to view results on a tablet or monitor to discuss them directly with the customer.

Trolley? That's Yesterday

- Display on Tablet, TV, PC or Smartphone!

- No PC-trolley: image processing directly inside the sensor head

- No printer: reports available as PDF files directly on the network

Measurement values? Wherever you need them

- Camber, caster, toe on four small screens directly under the vehicle

- Two hands free for adjustments and the values always in sight

- Stand up tall and make adjustments in any lift position, not just one

Wheel alignment? Made easy

- Use any target on any wheel to reduce setup times and errors

- Caster sweep without a stool or ladder, conveniently with the lift on floor level

- Intuitive software processes and menus

- Permanent left-right reference for guaranteed straight steering wheels

Space problem? No problem

- Permanently space in front of the lift

- Fits on any alignment lift

- Wireless and battery-powered

- More space in the workshop with MB Q.Lign

Call us now on 01823 328530 for more details

1. Scan VIN

- Scan the VIN on the windscreen or vehicle registration documents directly with the tablet

- No typing

- No typos

- No wasting of time

2. Scan online query

- Scanning the VIN automatically starts the online query

- 24/7 online access to the latest vehicle specs

- No constant installation of new databases

- OEM vehicle specs directly from Mercedes-Benz

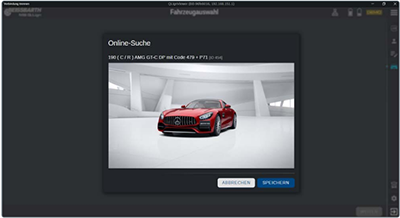

3. Automatic Vehicle Collection

- Complete selection of vehicle specs including equipment codes

- No manual fine selection necessary

- Automatic processing and display of the correct specs in the wheel aligner

- Clear vehicle-specific work instructions and graphics for the entire adjustment process

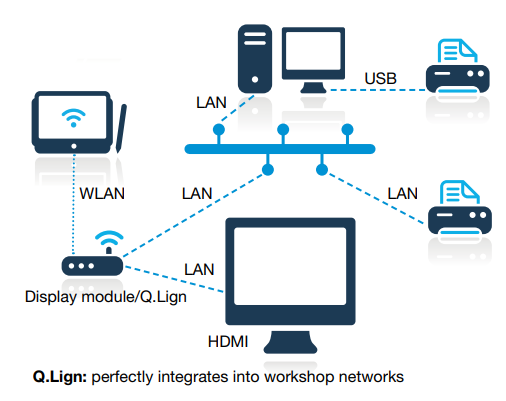

MB Q.Lign platform: More performance through connectivity

Connecting MB Q.Lign into the workshop network enables:

- Direct access to all measurements across the entire workshop network

- Direct download of PDF printouts for sharing with insurance companies or customers

- View measurements on a tablet or monitor to discuss them directly with the customer on site

- Use of network printers to minimize walking distances and costs

- Permanent supply of program updates over the air (OTA) (in preparation)

Call us now on 01823 328530 for more details

Scope of Delivery

- MB Q.Lign sensor heads (2x)

- Display module with MB software

- Magnetic clamps | 75 mm (4x)

- Targets with AutoID (4x)

- Android tablet with protective case

- Brake lock and steering wheel lock

- Precision turntable with fillers (2x)

- Wall mount for sensor heads

- Li-ion batteries and charging station

- Inground lift adapter (2x)

- RS232 to USB 2.0 adapter

- Mercedes-Benz vehicle database

- Vehicle database for other manufacturers

Technical Data

| Part Number | 1 690 200 010 |

| Wheelbase | 1,500 – 5,000 mm |

| Measurement and adjustment at lift height | Any height from bottom to top |

| Bolt pattern and PCD for magnetic clamp | 3 / 4 / 5 / 6 bolt pattern | Ø 98-140mm |

| Power supply | 100 – 230 V | 1 Ph | 50 – 60 Hz |

| Output | 45 W |

| Total Weight | 80kg |

| Weight of sensor head | 6kg |

| Battery runtime | >19 h |

| Lift adaptation | Adds min. 12 mm to outside of lift rails |

Optional Accessories

- Trolley 27“ monitor, mouse and keyboard. Part number: 1 690 201 142

- Accessory trolley OE clamps for OE quick clamps, steering wheel lock, and brake lock. Part number: 1 690 101 127

- Wall Bracket OE clamps for OE quick clamps (4 pcs.). Part number: 1 690 101 090

- Toe-spreader bar. Part number: 1 693 600 001

- Printer. Part number: 1 693 770 415

- Romess inclinometer with standard adapter. Part number: 1 693 770 002

- Romess adapter for M-Class (W163) for front and rear axle. Part number: 1 690 102 216

- Data/charging station for Romess inclinometer 230 V. Part number: 1 693 770 003

- Romess adapter for Vaneo (W414). Part number: 1 693 770 004

Call us now on 01823 328530 for more details